Printing technology is a rapidly changing world and one of the latest innovations in printing technology is DTF printing. Read on to find out what is a DTF printer, what advantages it has compared to other printing methods, and how it is used. So in this blog, I will be taking you through the technology of DTF printers, their uses, and how they differ from other printing methods.

What is a DTF Print?

The process of direct-to-film printing, which is more commonly known as DTF stands for direct-to-film printing, is the process of printing your designs directly onto a special film. They print the image in reverse on the film and apply a layer of adhesive powder. You use a design to transfer to the desired surface, such as fabric, and then heat the powder.

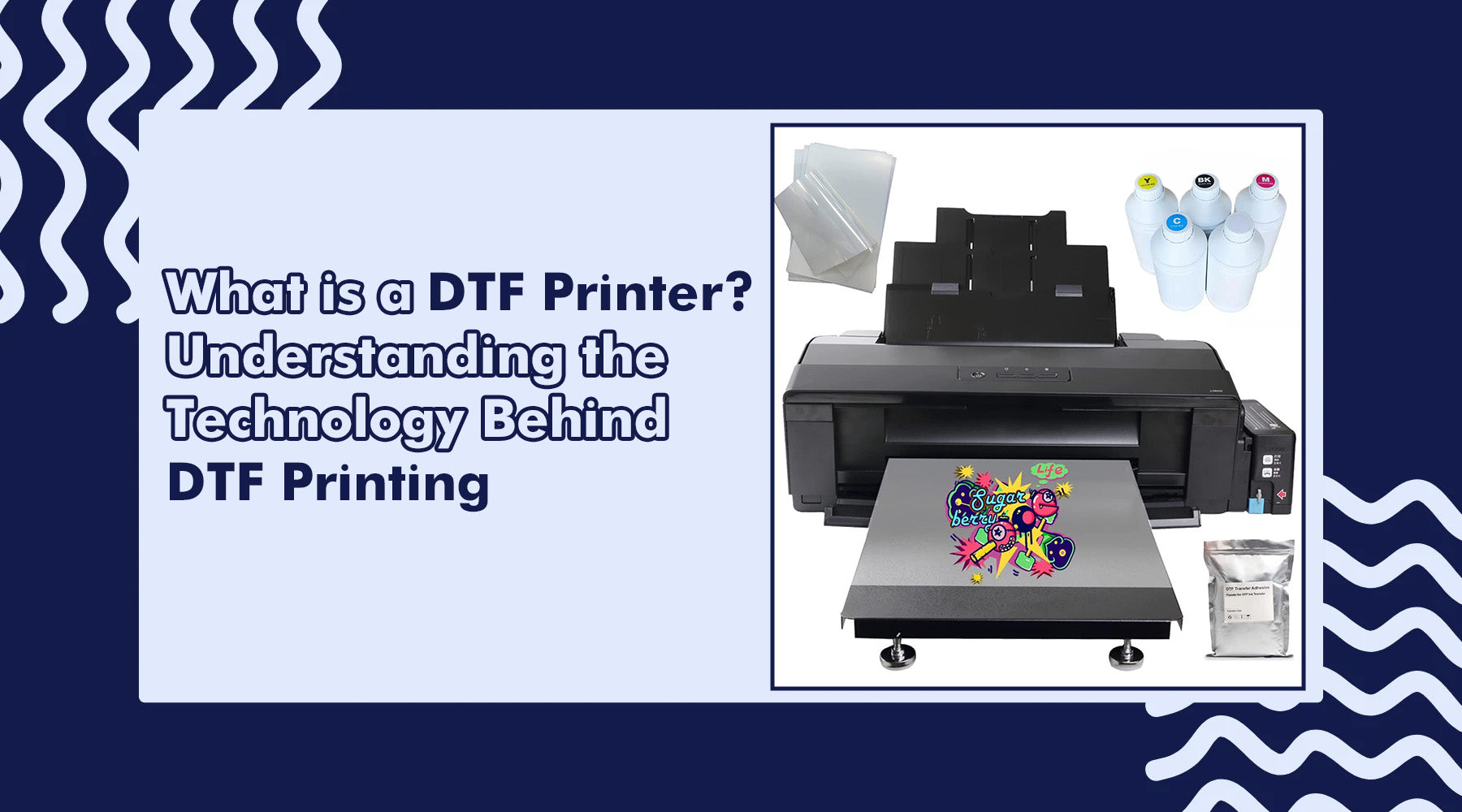

What are DTF printers?

The DTf printer (Direct to Film printers) are specialized printing machines that print designs onto a special transfer film. When the design is printed, the film is ‘coated’ with adhesive powder and heated to activate the adhesive. This enables the design to be ‘pixelated’ onto a wide range of materials such as fabrics; cotton, polyester, etc.

Unlike screen printing or sublimation, DTF printers are more flexible as they can print on fabrics and materials other than what they were designed to print on. Garment industry people like them for customizing apparel, having vibrant colors and intricate comes.

Also Read: What Does DTF Mean in Printing?

Key Features of DTF Printers:

- Direct to Film Process: DTF printers do what they sound like print designs onto special transfer film, then apply that to fabric using heat and adhesive powder.

- Versatile Fabric Options: DTF printers can print on cotton, polyester, silk, and blended fabrics and do not require any pre-treatment of the fabric.

- Vibrant Colors and Fine Details: Vibrant and detailed prints with high resolution — are great for intricate designs.

- Durable and Long-Lasting: DTF printer prints are durable and resistant to multiple washes and common wear, not fading or cracking.

- Cost-Effective: DTF is a high-cost efficient process for small and large-scale production as it requires no expensive setup and you don't need multiple printing screens.

- Easy to Use: The process is easy to follow, and, being as simple as it is, it is perfect for beginners in the garment printing industry as well as professionals.

What is a DTF Printer Used For?

In the garment industry, customizing apparel is mainly used for a DTF printer. DTF printers can create easy high-quality, durable designs on almost any fabric type—from T-shirts to tote bags. DTF printing, as the name suggests works by shooting the design onto a thin film and then transferring it.

For printshops or small businesses offering a broad range of design options, without the limitation of specific fabric types, DTF printers are fantastic! Regardless of which fabric you’re printing on, DTF printers can do their job with ease and precision.

Also Read: How to Print DTF Transfers?

What is a Good DTF Printer?

Therefore, when choosing a good DTF printer, there are several factors you need to keep in mind print quality, speed, and durability. The best DTF printers on the market have brands such as Mutoh, Epson, and Brother. These printers are famous for their reliability and excellent print resolutions.

And if you’re going for a professional setup with a printer, curing oven, and adhesive powder shaker, you may want to invest in a complete DTF printing system. This allows the systems to produce smoothly and efficiently when needed and to handle large orders practically without a problem.

What is a UV DTF Printer?

A UV DFT printer is a direct-to-film printer using ultraviolet (UV) curing technology. Unlike typical DTF printing meaning which needs heat transfer to print the image, UV DTF uses ultraviolet light to cure the image onto the film. The faster process means printing is more quickly achieved as well as prints on a wider range of materials than previously possible, including plastics, glass, and metal.

UV DTF printers are particularly useful for non-fabric applications, such as customizing phone cases, mugs, and other accessories.

Key Features of a UV DTF Printer:

-

Instant UV Curing: UV light cures the ink directly so printing and drying time is minimal, but also fast.

-

High Durability: They are also resistant to scratches, fading, and environmental wear so the prints do last.

-

Vibrant Colors: Sharp and vibrant colors are characteristic of UV DTF printers, they’re especially good for printing out detailed and complex designs.

-

Versatile Applications: You can print on metal, glass, wood, plastic, and much more.

-

Eco-Friendly: Where it is used, UV printing is more environmentally friendly as it creates less waste and uses fewer chemicals.

-

No Pre-treatment Required: Unlike other methods, UV DTF printing usually requires no prep work or pre-coating of the material.

Also Read: What is UV DTF?

Conclusion

There is no doubt that DT F printing is now a ‘go-to’ choice for producing exciting and high-quality prints on many fabric surfaces. Being able to print virtually anything, be it wood, fabric, paper, silicone, plastic, or glass, and produce beautiful rich detailed designs that other printing methods simply can’t produce, DTF printers are so versatile, therefore, they hold numerous benefits that cannot be compared to other methods.

DTF printing meaning is a reliable, cost-effective way to do your custom apparel printing, whether you are a small business trying to expand your offerings, are a hobbyist looking to level up, or are just someone who needs to print photos at home. With DTF printers, there are no limits as to what fabric type or color combinations you can explore.

Ready to take your printing game to the next level? Explore our range of high-quality DTF printers and accessories at DTFNC. Whether you’re starting a new business or upgrading your current equipment, we’ve got everything you need to bring your designs to life!

FAQs

What Does a DTF Printer Do?

A DTF printer prints designs onto a special film, which is then transferred onto a variety of fabrics or materials using adhesive powder and heat. DTF printers allow for full-color, high-detail prints on almost any surface, making them a versatile choice for custom printing.

Can I Print DTF on a Regular Printer?

No, you cannot use a regular printer for DTF printing. DTF printers require specialized ink, film, and equipment designed for the transfer process. Using a regular printer would not yield the desired results and could damage the printer.

Is DTF Better Than Sublimation?

The answer depends on your needs. DTF printing offers more flexibility because it works on a wider range of fabrics, including cotton, which sublimation cannot. Additionally, DTF prints can handle intricate designs with vibrant colors. However, sublimation is often faster and provides excellent results on polyester fabrics. If you need versatility in fabric types, DTF printing may be the better option.

What Do You Need for DTF Printing?

To start DTF printing, you will need the following equipment:

- A DTF printer

- DTF film

- Special DTF inks

- Adhesive powder

- Heat press or curing oven

This complete setup ensures that your designs are printed accurately and transferred smoothly onto the fabric.

3 comments

dtf transfer

Harness the power of dtf transfer capabilities, where seamless design application meets remarkable quality. Ideal for small or large orders, this printing tech delivers flawless results every time.

🔎 Reminder; Withdrawing №GD83. NEXT =>> https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=1ce1202d59a15b8016c3a74a232dbd1d& 🔎

oricrq

Marley

Could you take out all the black in the image